Most often a torque wrench is what we will use to test torque.

Torque test standards for bolts.

Astm f543 standard specification and test methods for metallic medical bone screws.

Reduce value by 10 if threads.

International test standards and methods.

Asme standards for testing torque tools according to total quality management by jack pekar torque wrenches are tested for torisional strength based on asme standard b18 6 4 while they are tested for hex socket strength according to astm f912.

Torque tension reference guide printed in u s a.

You can utilize it for most kinds of fasteners even nylon screws.

It is applicable basically to bolts screws studs and nuts made of carbon steel and alloy steel whose.

Astm d5649 standard test method for torque strength of adhesives used on threaded fasteners.

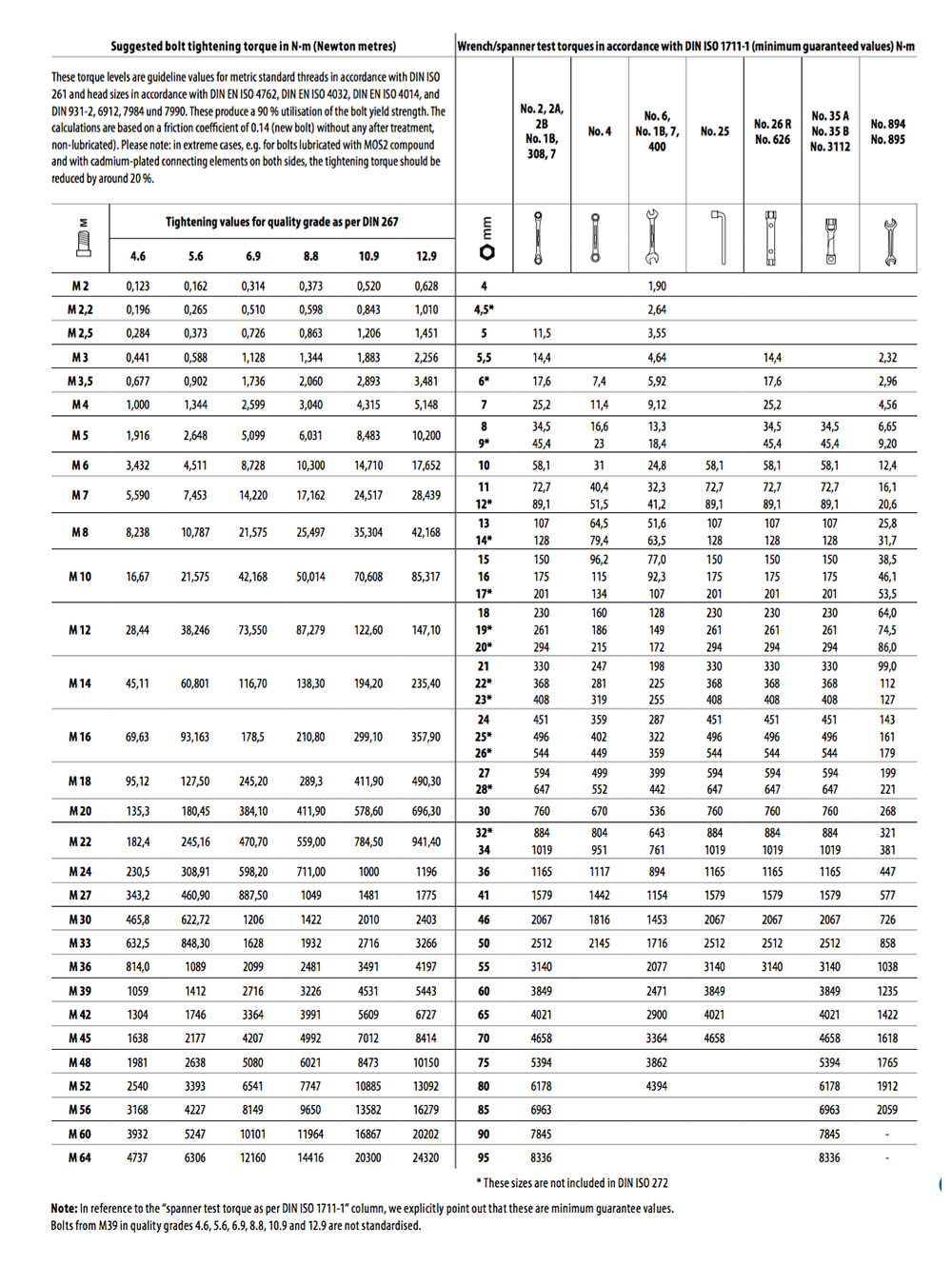

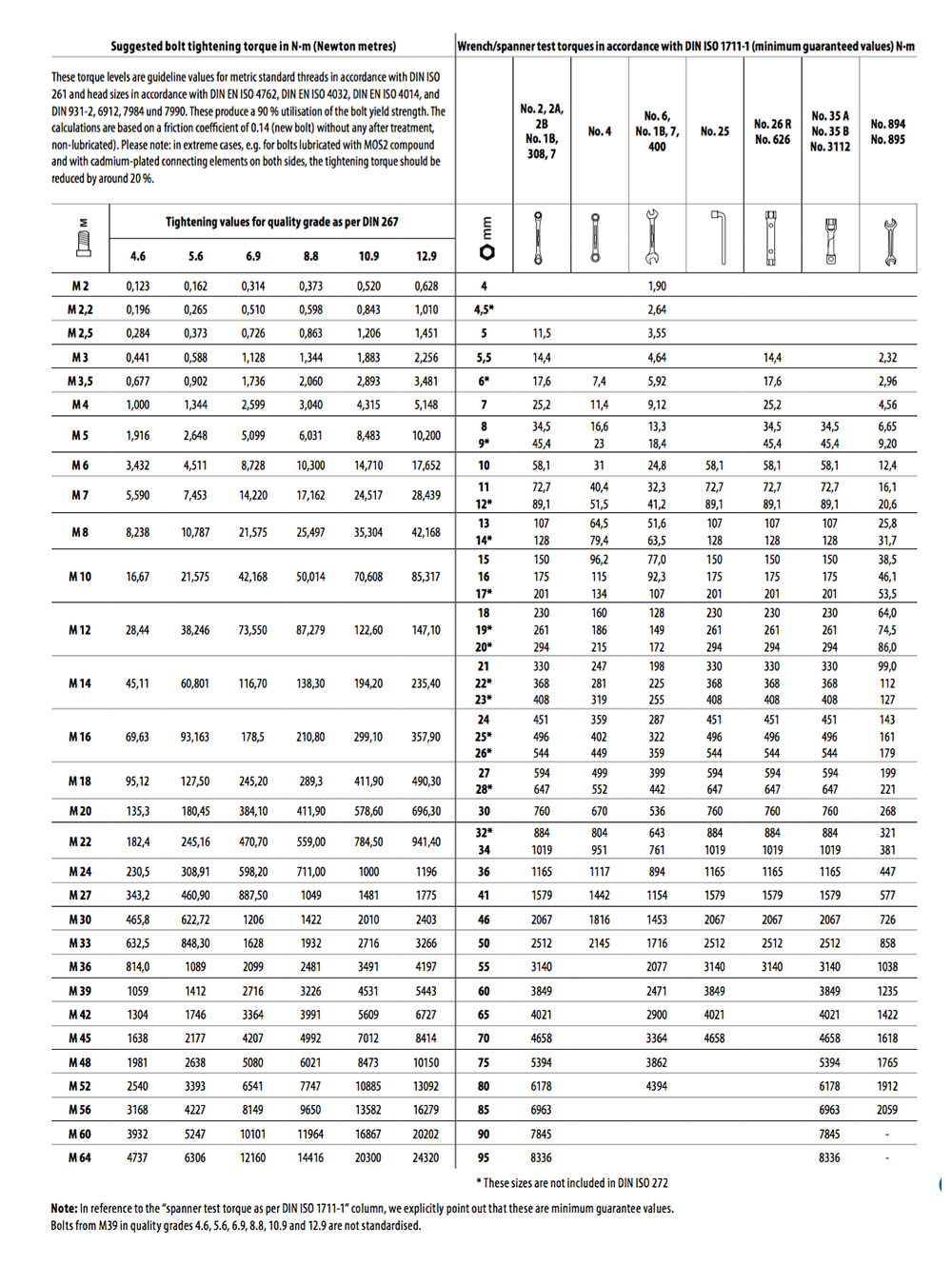

Torque values are based on clean dry threads.

One of the main plus point of utilizing this test is the fact that it is easy to do.

The torque necessary to resume the bolt to its initial position is the torque value of the bolt.

Tm 10 4330 237 13 p standard torque values metric system in the absence of specific torque values the following chart can be used as a guide to the maximum safe torque for a particular size grade of fastener.

The torque value to loosen the fastener is the approximate torque that was applied to the joint.

Standards for the torque tension relationship in fasteners cover tests for determining it on both externally and internally threaded fasteners tightening procedures and quality control methods for those procedures as well as laying out the interactions between all the applicable variables at play between different physical forces.

In threads per inch 307a astm a307 grade a sae j429 grade 5 sae j429 grade 8 f n l g 9 fnl grade 9 clamp load lbs tightening.

For longer fasteners the torque is reduced significantly.

At the point the fastener breaks loose the torque reading is recorded.

3 marking test once the fastener tightened mark clearly the surface of the fastener nut or bolt and continuing the mark onto the surface being clamped for reference.

Fastening torque fastening torque.

Clamp loads are based on 75 of the minimum proof loads for each grade and size.

Grade 2 calculations only cover fasteners 1 4 3 4 in diameter up to 6 long.

There is no torque difference for fine or coarse threads.

It is applicable basically to bolts screws studs and nuts made of carbon steel and alloy steel whose mechanical properties are specified in iso 898 1 iso 898 2 or iso 898 6 having iso metric threads.

Bs en iso 11608 2 needle based injection systems for medical use.

Supply part number.